Intelligent Factory Solution Offering

Implement our Intelligent Factory Solution for Insights to your Manufacturing Processes

By IoT enabling your manufacturing processes, you can gain significant benefits and business value by getting deeper insights into how your processes are operating, and using this insight into optimizing these processes.

A Few of the Benefits our Customers have Realized Include:

- Deeper insights into device telemetry data and the ability to collect this telemetry data in real-time

- Using this real-time telemetry to gain deeper insights into your manufacturing processes and process efficiency (OEE)

- Integrating real-time telemetry into Machine Learning rules engines to provide early-warning anomaly detection for predictive maintenance & predictive analytics

- Integrating the early-warning anomaly detection with Connected Field Service to proactively schedule plant equipment maintenance, which eliminates unscheduled down-time and lost productivity

Our Industrial IOT Intelligent Factory Solution Offering obtains the raw telemetry data from your devices, which empowers you to better manage and operate your factory floor. Best of all, we can have this implemented for you as quickly as two weeks!

Technical Details of our Intelligent Factory Solution Offering

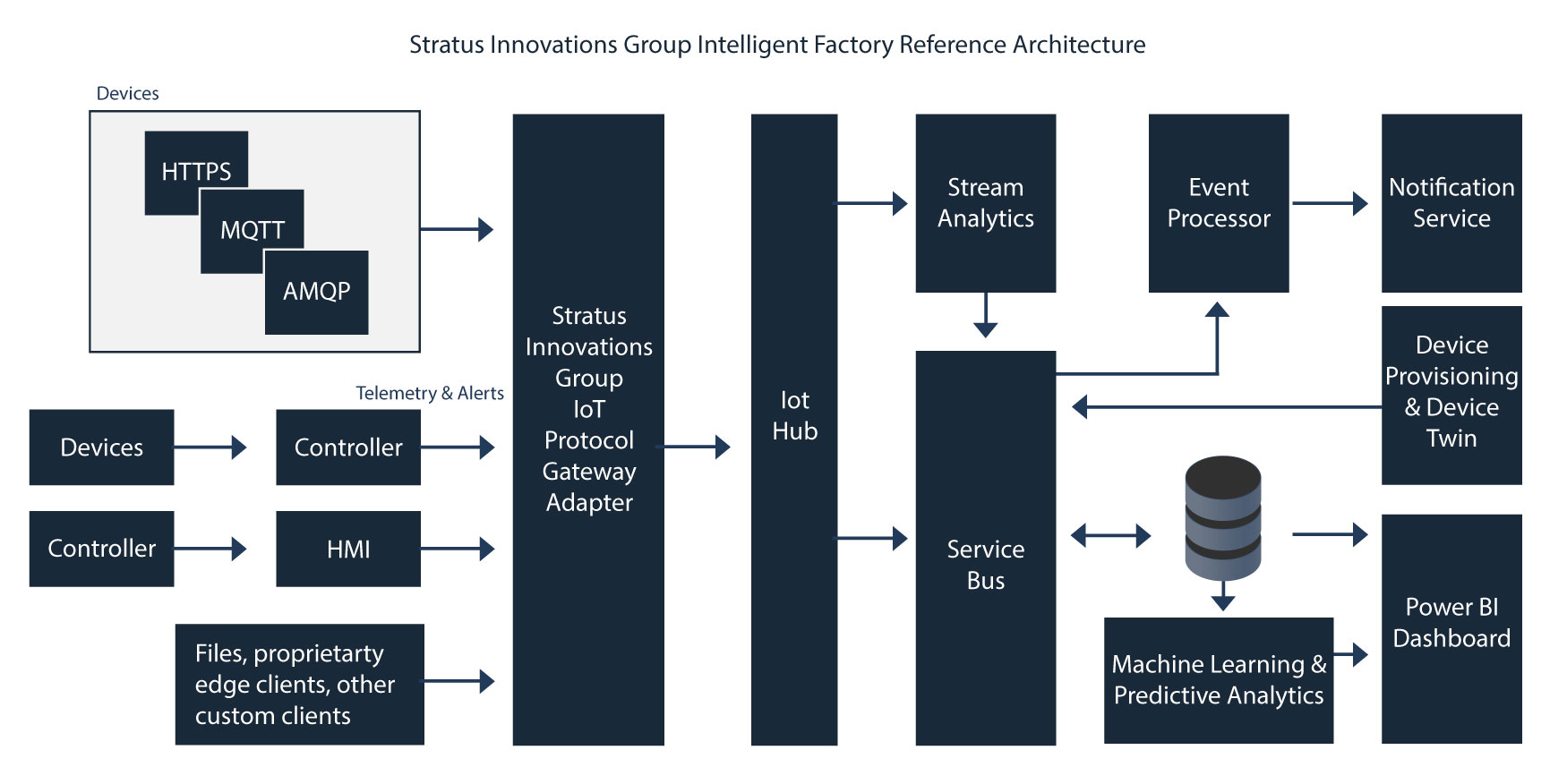

Our Intelligent Factory Solution Offering is the answer. The key piece of our architecture is the Stratus Innovations Group IoT Protocol Gateway Adapter™. Organizations can install or compile this collection of software libraries on any platform to quickly and easily connect to a centralized IoT hub that can work with:

- Devices that support disparate protocols (such as MQTT, AMQP, HTTPS, etc.)

- Controllers and HMIs of any type

- Other proprietary edge-type software

Businesses can use the deep insights generated by a fully integrated IoT ecosystem such as this to:

- Maximize quality, efficiency, and output

- Predict device issues and perform preventive maintenance

- Proactively manage machine loss and replacement

Learn More About Stratus Innovations Group’s Intelligent Factory Solution Offering

8000 Walton Parkway

Suite 200 New Albany, OH 43054